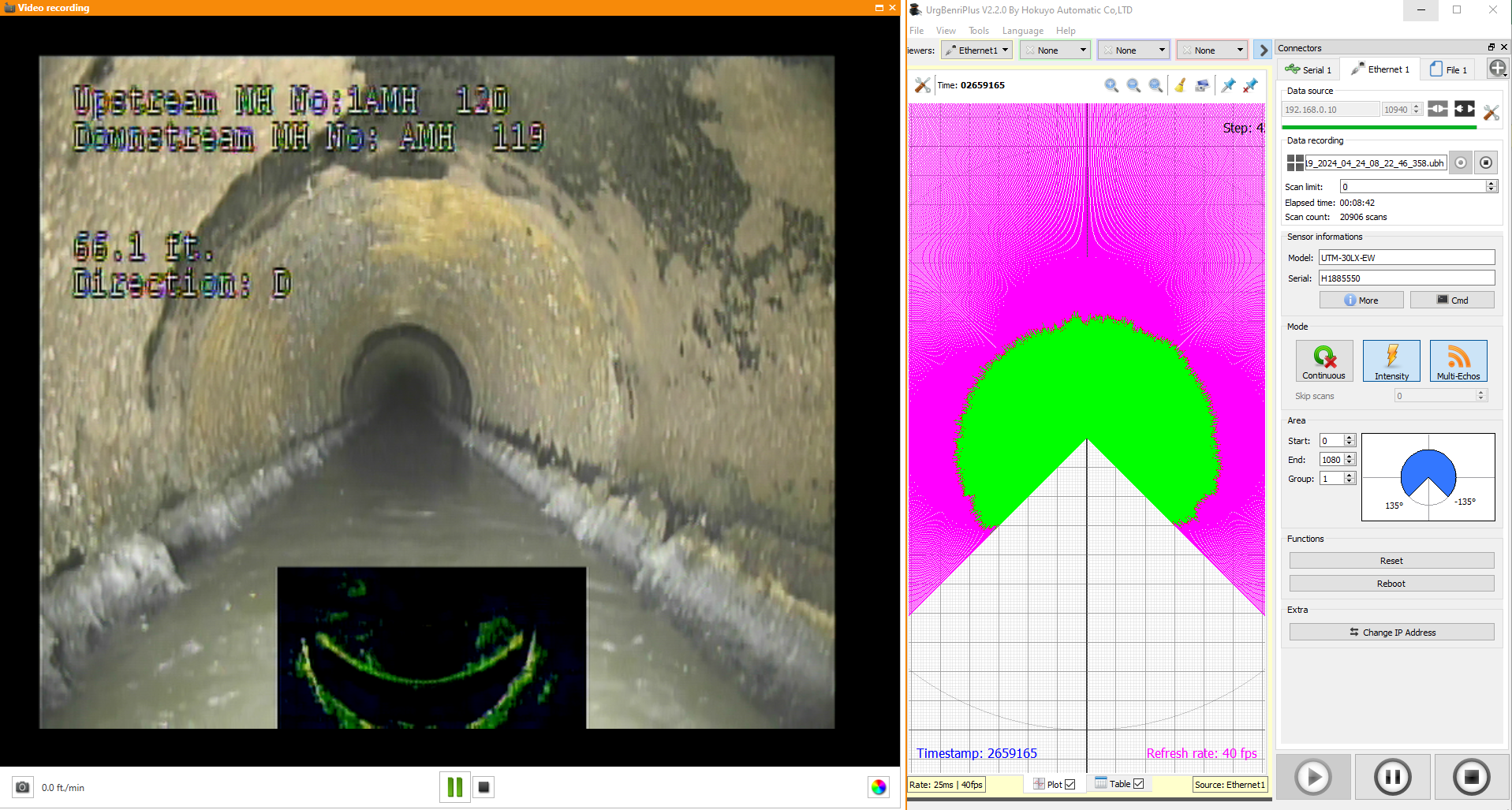

At CES, we recommend Sonar and Multi-Sensor technologies for inspecting large-diameter pipes (18” and above), providing a full 360-degree view of the pipe above and below the waterline. Sonar inspections are designed to give you a clear picture of sediment buildup, capacity loss, and structural damage.

Our Multi-Sensor units gather important data without bypass costs, while Sonar technology is implemented to accurately measure debris levels. LiDAR technology pinpoints interior corrosion, deformation, and ovality in large-diameter pipes. By combining sonar imaging for submerged conditions, LiDAR scanning for dry areas, and CCTV technology for visual clarity, we provide precise data for your maintenance and compliance needs.

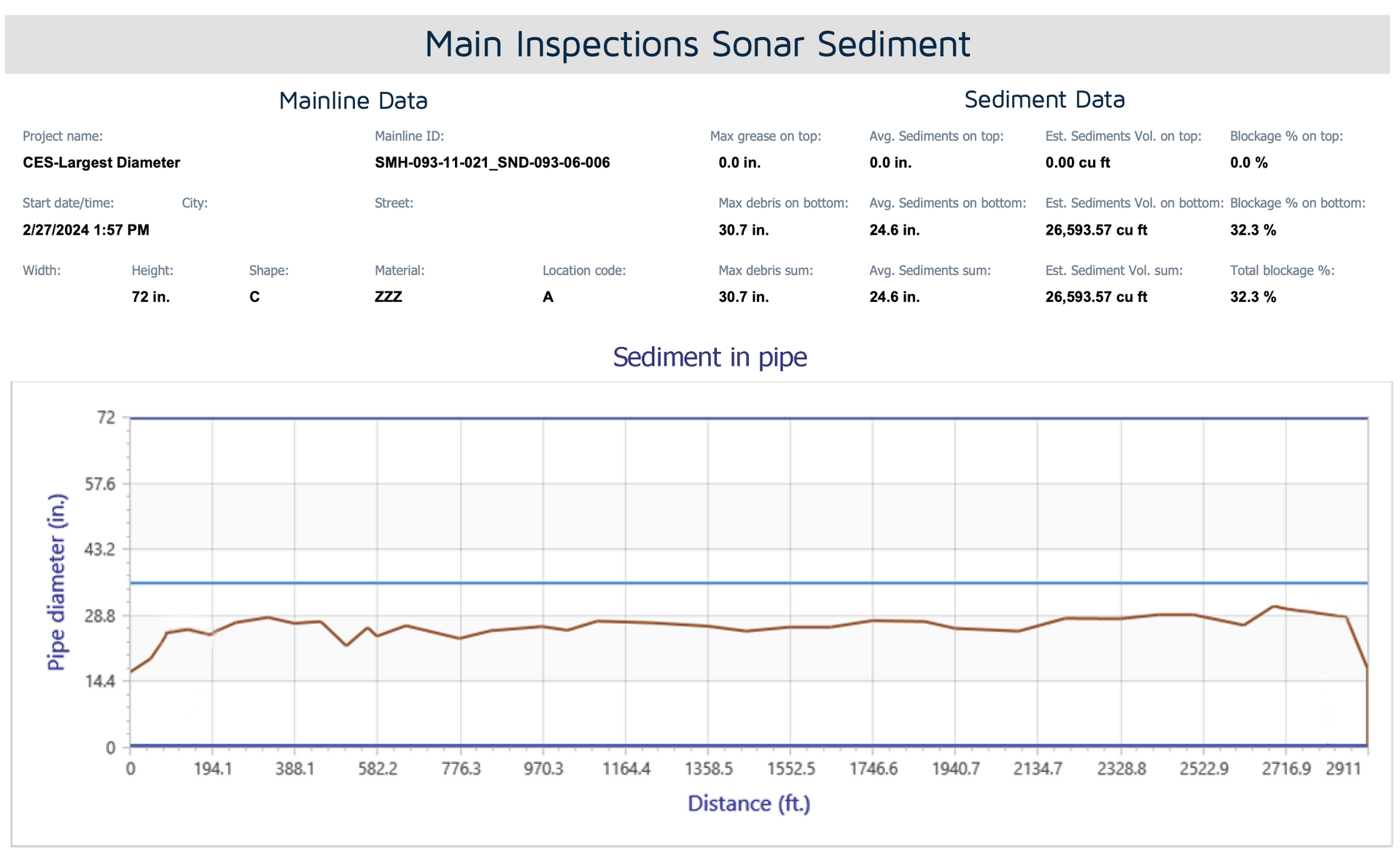

CES’s inspection reports provide data that helps clients focus resources only where necessary, reducing costs for road building, manhole access, and cleaning services. By mapping debris levels, our reports determine which pipes require cleaning, saving significant costs compared to cleaning every segment. Our deliverables allow office viewing with virtual pan, tilt, and zoom.

Interceptor Evaluation Project Spotlight

CES recently completed a 17-mile trunk line inspection, evaluating pipes ranging from 42” to 96” in diameter.

Challenges included:

- High Debris Levels: Our sonar inspections pinpointed problem areas, allowing us to save the client significant cleaning costs.

- Floodplain Manholes: With manholes stacked 30 feet above grade, we deployed certified scaffolding crews to access these locations safely.

- Cost-Effective Cleaning Plans: By identifying which segments required cleaning, the client avoided unnecessary road building and reduced overall expenses.

frequently asked questions

Why choose CES for Sonar/Multi-Sensor Inspections?

Since 2013, CES has completed hundreds of Sonar/Multi-Sensor Inspections across the Southeast, helping clients reduce expenses and improve system reliability. Our mission is to help clients avoid unnecessary cleaning costs by targeting only the segments that need attention.

Our experts are ready to tackle even the most difficult large-diameter pipe inspection challenges with cutting-edge equipment, proven expertise, custom solutions, and precise data deliverables.

Backed by proven expertise, advanced training, and cutting-edge technology, CES is committed to delivering reliable, cost-effective solutions for any pipeline—no matter the size, flow condition, or location.

What challenges do large-diameter pipe inspections pose?

Large-diameter pipes, particularly trunk lines, pose a myriad of unique challenges. High flow levels can obstruct traditional CCTV cameras, leaving the submerged portions of pipes uninspected.

Sediment buildup and debris accumulation reduce flow capacity and may cause backups, sanitary sewer overflows (SSOs), or strong odors escaping through manholes. Corrosion and structural wear due to H2S gas can lead to collapse over time.

Additionally, municipalities often mandate post-installation LiDAR inspections for new pipe installations to verify ovality and joint spacing compliance. These challenges require specialized solutions that combine precision, efficiency, and accessibility.

How do CES’s Sonar/Multi-Sensor Inspections help clients adhere to compliance regulations?

We deliver thorough evaluations of your system or trunk line’s structural integrity so you can address problem areas to satisfy EPA-mandated consent decrees and municipal requirements for post-installation inspections.

How does CES access remote areas?

CES’s motto is Any Pipe, Anywhere. With an unmatched fleet of off-road equipment, including 4-wheelers, track machines, and Marsh Masters, we reach pipes in even the most remote locations.

From scaffolding setups to custom solutions, we ensure every inspection gets done, no matter the access challenges.

Learn more about our off-road capabilities here (link will be included).