Prevent Natural Gas Cross-Bores in Sewer Systems

Since the 1970s, gas utilities and contractors have utilized trenchless technologies such as moles, plows and Horizontal Directional Drilling (HDD) to install natural gas pipelines across the United States.

The equipment is specifically designed to drill through almost anything, including sanitary sewer mains and laterals, storm drainpipes, sewer force main pipes, water mains and other utilities. This is known as a cross bore – the accidental intersection of one underground utility with another utility.

When a utility is bored through a sewer force main or water main, you know it almost immediately because you can typically see the result above ground. It will look like the famous Old Faithful Geyser in Yellowstone National Park. However, when a utility is bored through a gravity sewer main, sewer lateral or storm drainpipe, the cross bore can likely remain undetected until it is too late.

Why are undetected cross bores an issue?

Costly Damage and Overflows

Boring through gravity sewer and storm drainpipes wreaks havoc on those utilities, causing an enormous amount of inflow/infiltration (also known as groundwater and rainwater and is commonly referred to as I/I) and debris to enter into the sewer system. When this occurs, the owner of said sewer system can unnecessarily spend millions of dollars by having to pump I/I with lift stations. Lift stations require power to operate, so electric bills will rise sharply and there will be increased wear and tear on pumps which will need to be replaced eventually due to overuse. The owner of the sewer system will also be paying a massive amount of money to treat the I/I at their wastewater treatment facility, which is required by the Environmental Protection Agency (EPA). Inevitably, cross-bores can also cause Sanitary Sewer Overflows, an occurrence in which sewer spills into streets, waterways and even homes.

Lack of Tracer Wires

One-call tickets are typically required when a contractor is boring natural gas pipes. The issue here is that in most cases the sewer mains and laterals will not be located as part of this process because these pipes are usually installed without tracer wires, so they are not easily located through standard One Call practices. Therefore, the gas boring contractor will not know the location of the sewer mains and laterals.

Gas Explosion/Migration Risks

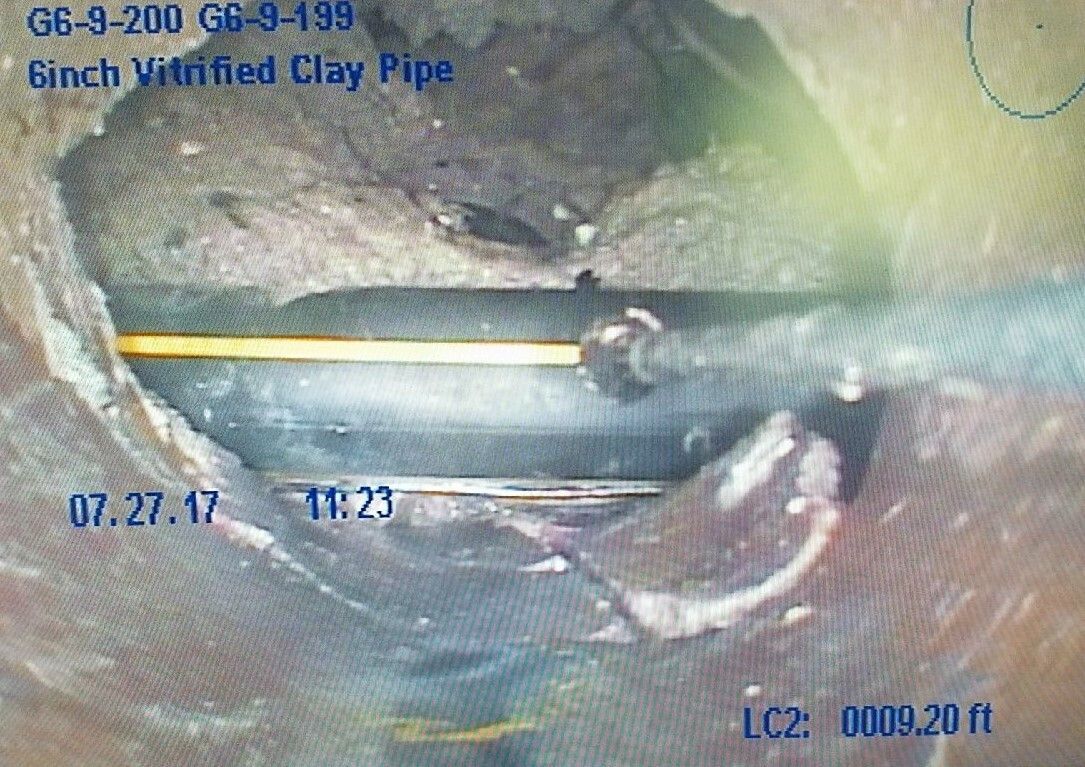

Routine cleaning of gravity sewer mains and sewer lateral pipes often requires the use of cutting tools to remove grease, roots and other debris to allow the sewer to flow via gravity through the pipes. If there is a natural gas cross-bore present in the sewer pipe, the cutting equipment will destroy the gas pipe, potentially causing an immediate explosion or allowing gas to migrate through the sewer system into nearby homes/businesses.

Preventing and Locating Natural Gas Cross Bores with Advanced Sewer Inspection Technology

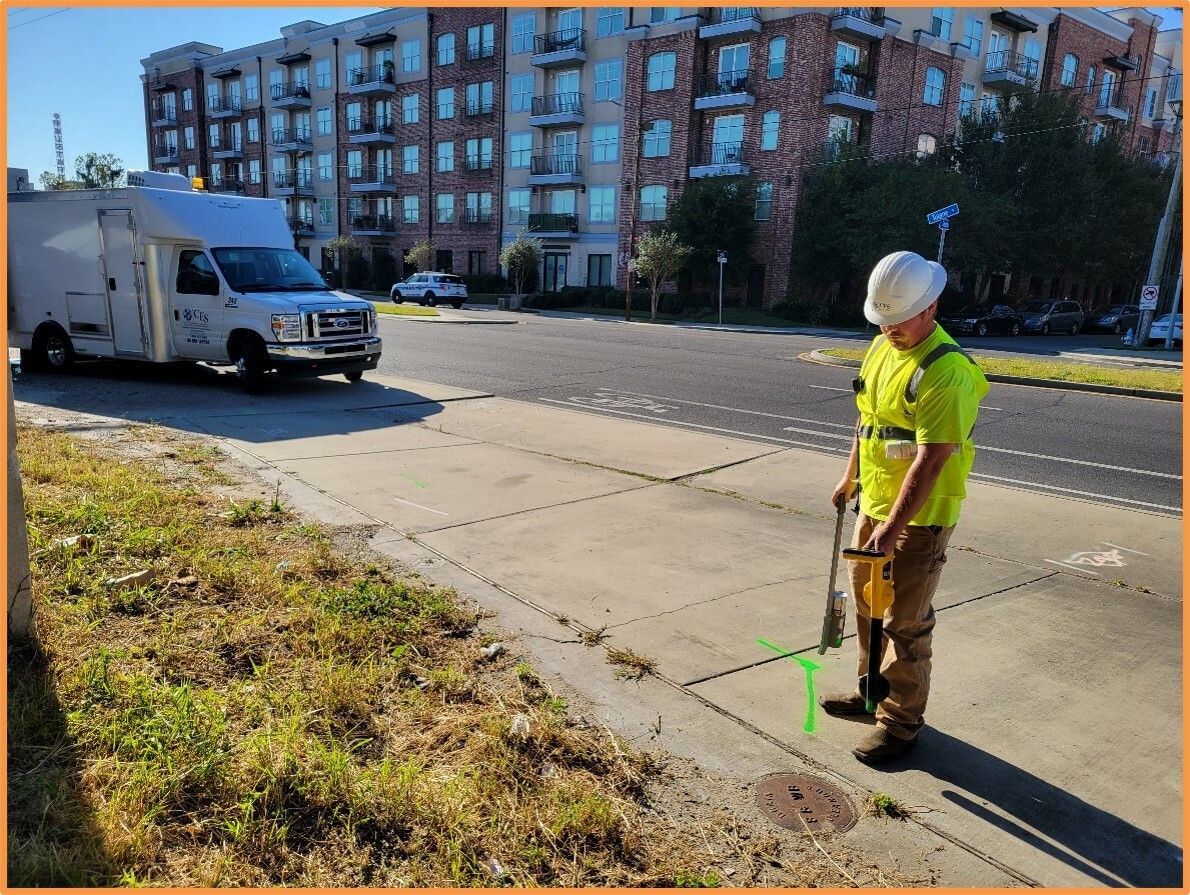

Pre-Bore Locates

When performing PRE-bore sewer locates, CES uses a variety of sewer inspection cameras that contain sonde frequency transmitters. CES’s cameras are custom-built and designed to video the sewer main and then launch up into the sewer laterals from the sewer main. While tracking the sewer camera (and sonde frequency transmitter) above ground, CES is able to collect X, Y and Z (depth) GPS data on the sewer pipes below ground.

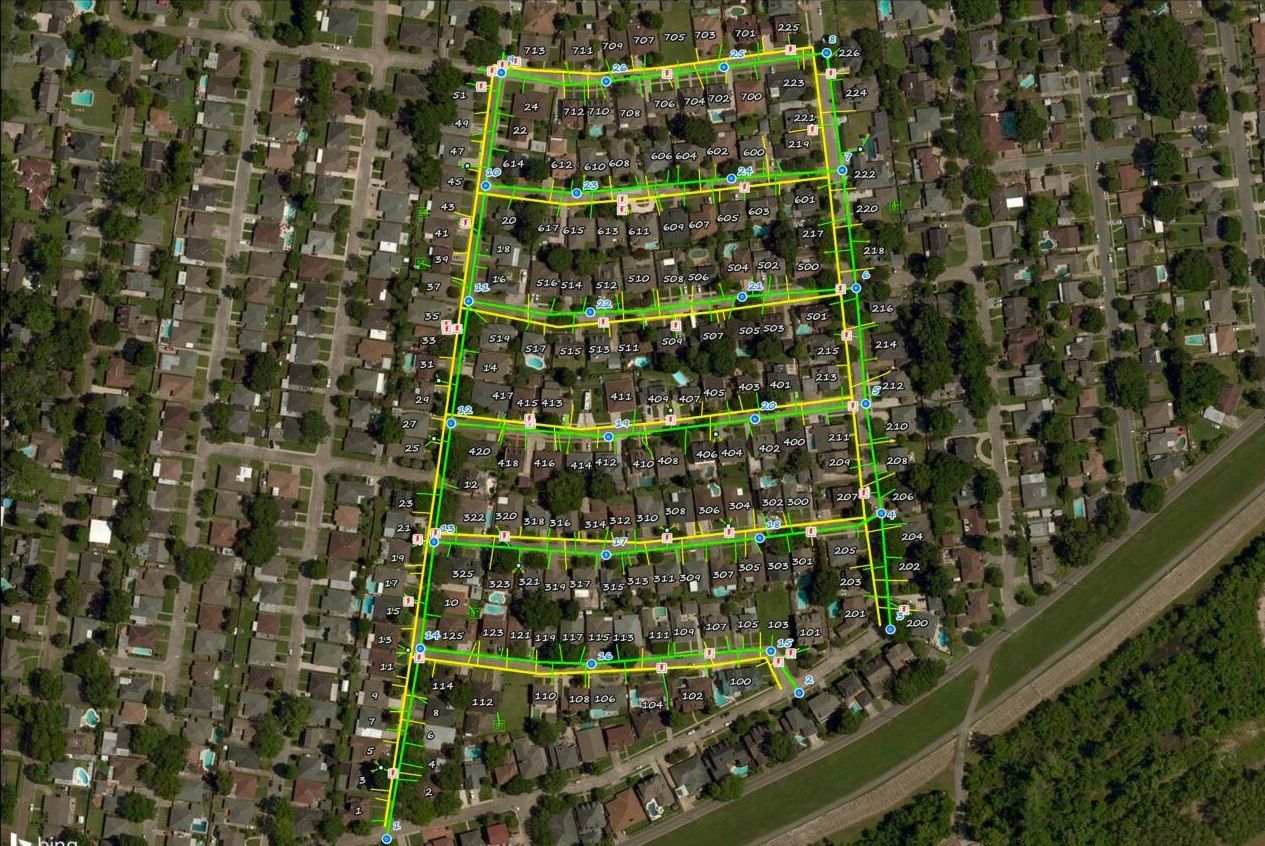

CES will provide the GPS data to the gas utility and/or the gas boring contractor via easy-to-read digital maps that can be viewed in real-time from a smartphone, tablet or laptop in addition to locate marks that CES places on the ground. When these maps and marks are utilized before boring new pipes in the ground, historical data shows that there is less than 0.05% chance of a cross bore occurring. If this GPS data is NOT collected and maps are NOT utilized before boring new pipes in the ground, historical data shows that there will be a cross-bore in as many as 6-10% of sewer pipes. This is an alarming statistic because natural gas cross bores are essentially ticking time bombs, which can cause loss of life among many other things.

Post-Bore Inspections

When performing POST-bore inspections, it is imperative that a GIS map be created to account for all sewer pipes inspected (or not inspected), current location of all gas mains and gas laterals and all cross bores located. Without a map, sewer pipes will be unaccounted for and things will likely get overlooked. Also, mapping the current location of the gas pipes and sewer pipes can potentially save the gas utility millions of dollars simply by not inspecting pipes where there is no possibility of a cross-bore existing (based on the proximity of the 2 utilities to each other).